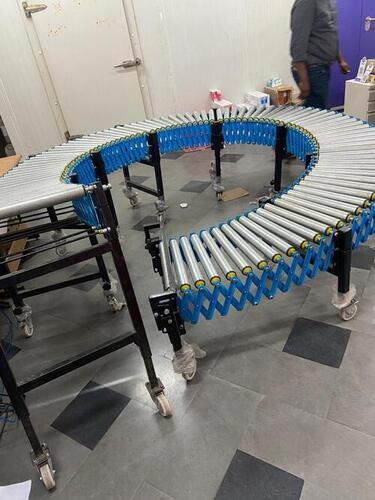

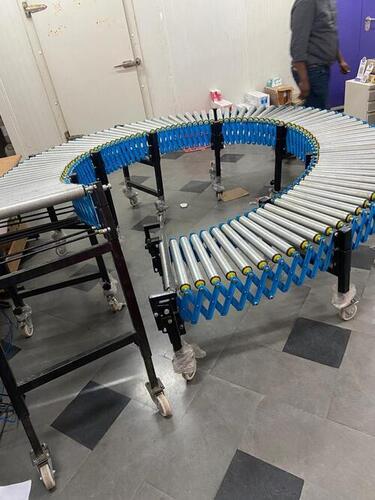

Gravity or flexible gravity Conveyor

Product Details:

- Size 50 feet

- Usage Industrial

- Material Metal

- Type Other

- Resistant Feature Other

- Load Capacity 50 kgs per meter Long Ton

- Voltage 220 Statampere (sA)

- Click to View more

Gravity or flexible gravity Conveyor Price And Quantity

- 1 Unit

- 150000 INR/Unit

Gravity or flexible gravity Conveyor Product Specifications

- Metal

- 50 kgs per meter Long Ton

- 20 box per min by sq m/hr

- Industrial

- Other

- 220 Statampere (sA)

- Other

- 50 feet

- 2 hp Biot ( Bi)

Gravity or flexible gravity Conveyor Trade Information

- 2 Unit Per Week

- 10 Months

- All India

Product Description

A roller conveyor is a kind of material handling device that moves objects from one place to another using a number of cylindrical rollers. For reliable and effective flow of items, it is a well-liked and adaptable conveyor system.

A roller conveyor's frame or structure, which is commonly composed of steel or aluminium, has several rollers equally distributed throughout its length. Items can be moved by pushing them manually or by using gravity thanks to the rollers' axle-mounted construction and free rotation. Depending on the requirements of the particular application, the conveyor may be horizontal or inclined.

Different load sizes, shapes, and weights can be accommodated by different configurations of roller conveyors. Typical types include:

1. Gravity Roller Conveyor: This kind of conveyor moves objects using gravity. Most of the time, it is adjusted to a little decline so that the goods can roll down the conveyor on their own weight. Gravity roller conveyors are frequently utilised in accumulation zones, order picking, and human material handling.

2. Powered Roller Conveyor: In a powered roller conveyor, a power source, such as an electric motor, drives the rollers. This allows for the automated and controlled transportation of goods along the conveyor. For smooth material flow, powered roller conveyors can be combined with other automated systems and are appropriate for handling higher loads.

3. This sort of roller conveyor allows objects to gather or queue up without running into each other or becoming damaged. For the purpose of restricting product movement and establishing spaces between them, it uses zones or sections equipped with photoelectric sensors or other technologies. In packing areas, shipping facilities, and assembly lines, accumulating roller conveyors are frequently employed.

4. Belt-Driven Roller Conveyor: A motorised pulley drives a belt that is wrapped around the rollers in a belt-driven roller conveyor. This arrangement offers more grasp and control over the movement of objects, making it appropriate for working with products that are delicate or have irregular shapes.

Roller conveyors provide many benefits, such as effective material handling, high load capacity, simplicity of installation, and minimal maintenance needs. They are extensively utilised in sectors including manufacturing, distribution, warehousing, and logistics where there is a demand for safe and efficient cargo movement.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+