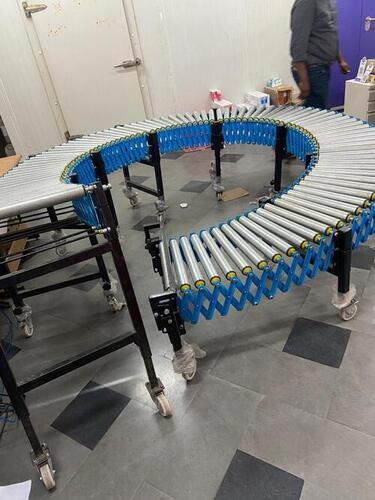

Gravity or flexible gravity Conveyor

Price 150000 INR/ Unit

Gravity or flexible gravity Conveyor Specification

- Usage

- Industrial

- Material

- Metal

- Size

- 50 feet

- Type

- Other

- Resistant Feature

- Other

- Load Capacity

- 50 kgs per meter Long Ton

- Voltage

- 220 Statampere (sA)

- Power

- 2 hp Biot ( Bi)

- Speed

- 20 box per min by sq m/hr

Gravity or flexible gravity Conveyor Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Week

- Delivery Time

- 10 Months

- Main Domestic Market

- All India

About Gravity or flexible gravity Conveyor

A roller conveyor is a kind of material handling device that moves objects from one place to another using a number of cylindrical rollers. For reliable and effective flow of items, it is a well-liked and adaptable conveyor system.

A roller conveyors frame or structure, which is commonly composed of steel or aluminium, has several rollers equally distributed throughout its length. Items can be moved by pushing them manually or by using gravity thanks to the rollers axle-mounted construction and free rotation. Depending on the requirements of the particular application, the conveyor may be horizontal or inclined.

Different load sizes, shapes, and weights can be accommodated by different configurations of roller conveyors. Typical types include:

1. Gravity Roller Conveyor: This kind of conveyor moves objects using gravity. Most of the time, it is adjusted to a little decline so that the goods can roll down the conveyor on their own weight. Gravity roller conveyors are frequently utilised in accumulation zones, order picking, and human material handling.

2. Powered Roller Conveyor: In a powered roller conveyor, a power source, such as an electric motor, drives the rollers. This allows for the automated and controlled transportation of goods along the conveyor. For smooth material flow, powered roller conveyors can be combined with other automated systems and are appropriate for handling higher loads.

3. This sort of roller conveyor allows objects to gather or queue up without running into each other or becoming damaged. For the purpose of restricting product movement and establishing spaces between them, it uses zones or sections equipped with photoelectric sensors or other technologies. In packing areas, shipping facilities, and assembly lines, accumulating roller conveyors are frequently employed.

4. Belt-Driven Roller Conveyor: A motorised pulley drives a belt that is wrapped around the rollers in a belt-driven roller conveyor. This arrangement offers more grasp and control over the movement of objects, making it appropriate for working with products that are delicate or have irregular shapes.

Roller conveyors provide many benefits, such as effective material handling, high load capacity, simplicity of installation, and minimal maintenance needs. They are extensively utilised in sectors including manufacturing, distribution, warehousing, and logistics where there is a demand for safe and efficient cargo movement.

Engineered for Efficient Industrial Conveyance

Our gravity and flexible conveyors are purpose-built for industrial applications, ensuring seamless transport of goods over long distances. The 50-foot size and 50 kgs per meter capacity allow for versatile, high-volume handling, reducing manual labor and boosting productivity.

Durable Construction & Superior Performance

Manufactured using premium metal materials, this conveyor is designed for longevity and robust performance. With a 2 hp Biot motor and 220 sA voltage, it operates steadily even in demanding environments, minimising downtime and maintenance requirements.

Comprehensive Support from an Indian Supplier

As an experienced exporter, manufacturer, service provider, and supplier in India, we provide end-to-end support, from consultation and installation to after-sales service. Our expertise ensures smooth implementation and optimal operation for clients worldwide.

FAQs of Gravity or flexible gravity Conveyor:

Q: How does the gravity or flexible gravity conveyor operate in an industrial setting?

A: The conveyor leverages gravity or a flexible design to transport goods efficiently along its metal structure. Powered by a 2 hp Biot motor and operating at 220 Statampere, it moves up to 20 boxes per minute per square meter, minimizing the need for manual intervention in industrial environments.Q: What material is used in the construction of this conveyor?

A: The conveyor is made from high-quality metal, providing durability and strength required to handle heavy loads, up to 50 kgs per meter, on a continuous basis without compromising structural integrity.Q: When is it ideal to use this gravity or flexible conveyor for industrial processes?

A: This conveyor excels in settings where frequent, high-volume transport of goods is necessary, such as assembly lines, warehouses, or packaging facilities, particularly when efficient movement and load reliability are critical.Q: Where is this conveyor available and who supplies it?

A: We supply these conveyors across India and internationally, acting as exporters, manufacturers, service providers, and suppliers, catering to industrial clients seeking reliable material handling solutions.Q: What is the installation process for the conveyor?

A: Installation involves site assessment, system configuration according to operational needs, assembling the 50-foot metal conveyor, and integrating the 2 hp Biot motor and power connections. Our service team ensures a smooth setup and provides training as needed.Q: How is the conveyor used for maximum efficiency in an industrial setup?

A: To optimize efficiency, the conveyor should be positioned to streamline workflow, handle the specified load, and maintain the speed of 20 boxes per minute per sq m/hr, ensuring goods are transferred swiftly between workstations.Q: What benefits does this conveyor offer over traditional transport solutions?

A: It offers increased throughput, reduced manual labor, enhanced safety, and dependable operation. Its flexible configuration and robust construction make it ideal for dynamic industrial environments, supporting productivity and cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flexible Roller Conveyors Category

Flexible Roller Conveyors

Price 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Roller Conveyor

Width : 500 Meter (m)

Structure : Other

Weight : 50 kgs per meter Drams (dr)

Send Inquiry

Send Inquiry