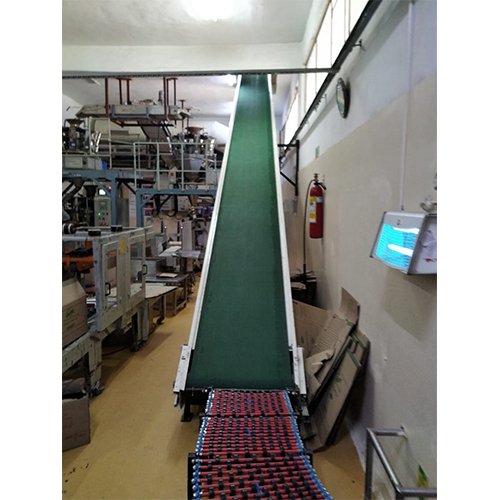

PVC Belt Conveyor

Price 200000.00 INR/ Bag

PVC Belt Conveyor Specification

- Usage

- Industrial

- Material

- Cast Iron

- Size

- Different Sizes Available

- Type

- Belt Conveyor

- Belt Conveyor

- Flat Belt

- Voltage

- 220-440 Volt (v)

- Warranty

- 1 Year

PVC Belt Conveyor Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia, Central America, Africa, Australia, Eastern Europe, North America, Western Europe, South America, Middle East

- Main Domestic Market

- All India

About PVC Belt Conveyor

PVC belt conveyors have the following benefits:

1. PVC belts are versatile and may transport a variety of goods and materials, including light to medium-weight objects like boxes, cartons, bags, and parcels. Both horizontal and incline transporting applications are appropriate for them.

2. PVC belts are known for their strength and resistance to wear, making them ideal for workplaces with high demands. They are resistant to wear, impact, and difficult working environments, ensuring long-term performance and lowering upkeep needs.

3. Cleanliness and hygiene: PVC belts are easy to clean and maintain because they are non-porous. They are appropriate for sectors like food processing and pharmaceuticals where cleanliness and hygiene are crucial because they are resistant to moisture, oils, and chemicals.

4. PVC belt conveyors provide a cost-effective option for material handling requirements. When compared to other conveyor belt kinds, PVC belts are reasonably priced, making them a cost-effective option for enterprises.

Conveyors made of PVC can be modified to fit certain application needs. Various conveyor parts and accessories, including driving systems, supports, guides, and safety features, can be added to them.

These conveyors are extensively employed in a variety of sectors, including manufacturing, shipping, packaging, and airports. They are frequently used in processes including product assembly, packaging lines, sorting, accumulation, and storage.

In general, PVC belt conveyors offer a dependable and effective method of moving goods in a variety of businesses. They are a popular option for material handling operations because of their adaptability, toughness, and affordability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry